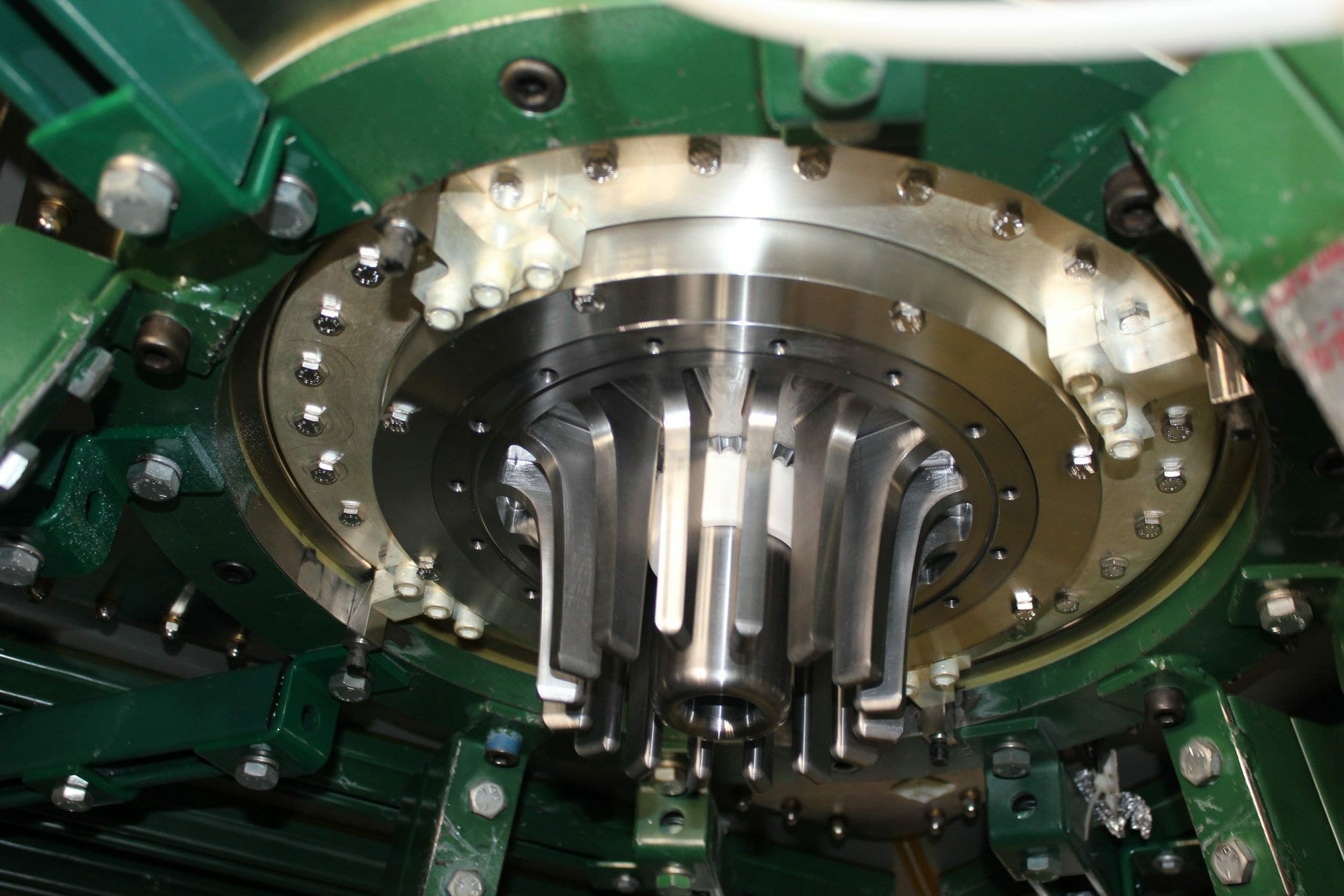

After nearly a year of preparation, on June 4th LPPFusion’s research team started a new series of experiments using for the first time beryllium electrodes in a plasma focus device (Fig.1). Before starting, we renamed our device Focus Fusion 2B or FF-2B for short. The new name stands for Beryllium electrodes and Boron fuel—which we expect to use late this year—and for “Focus Fusion to be”, the future of Focus Fusion.

Figure 1. The beryllium electrodes (anode is inner cylinder, cathode, outer vanes) during assembly (left) and inside the new vacuum chamber (right) have now started firing in our new experiment.

Figure 2. LPPFusion Director of Communications Ivy Karamitsos officially renaming our device “Focus Fusion 2B” or “FF2B” for short. Traditional renaming of people, such as knighting, used ancestral obsolete weapons (a king’s sword, for example). So our peaceful scientific ceremony used an ancestral obsolete scientific calculator—a slide rule! This slide rule belonged to Melvin Lerner, the father of LPPFusion Chief Scientist Eric Lerner. Melvin Lerner was a leading analytical chemist and scientific administrator, for over 20 years Director of Technical Service for the US Customs Bureau. He was a pioneer in the chemical analysis of marijuana and developed new techniques in statistical analysis and sampling.

After 44 shots to date, we have achieved our first goal of firing with low impurities. The electrodes are far smoother than the tungsten ones were after a similar number of shots, indicating better erosion resistance, as we expected. Fusion yield has risen 60-fold since the first shot and is now 1/10th of a joule. This is comparable with the best results achieved with the similar 10-cm long tungsten anode, but not yet above our record of ¼ J, achieved in 2016 with a longer 14-cm anode. We also have not yet observed the long-lived filaments that we hope to produce as a step to getting much higher fusion yield. That is our next goal.

Achieving low impurities

Our primary reason for replacing our tungsten electrodes with beryllium ones was to reduce impurities in the plasma. These impurities were, we hypothesized, increasing plasma resistance and causing the filaments to heat up too rapidly, destroying them. Without the initial increase in density caused by the filaments, final density in our plasmoids was too low, limiting fusion yield.

Since it is well known that resistance in plasmas increases with the square of atomic charge, or “z”, of the nuclei in the plasma, we needed a low-z material for the electrodes to reduce the impact of any impurities created by vaporized electrode material. With only four electric charges in its nucleus, beryllium was the best choice for a low-z material.

In addition, our tungsten electrode formed a deep, fragile, tungsten oxide outer layer, that was easily vaporized, unlike pure tungsten metal. We expected beryllium would be far better in this respect, and we were right, as it formed a self-limiting oxide layer only 10 nm thick. This could be removed rapidly during firing, we believed, and we made every effort to prevent significant oxygen from entering the chamber after we started firing. (See the section of Preparations, below).

We’ve achieved our initial goal of getting low impurity, although it did not look like we would, judging by the first shot. As expected, the first shot removed the layer of beryllium oxide, since it is an electrical insulator and the current had to pass through it to get to the beryllium metal below. What we didn’t expect was how much dust this would produce (see Fig. 3). Our electrode looked really dirty as it was totally covered in dark dust. We could roughly measure the amount of dust on the vacuum chamber windows, using our spectrometer. A thicker layer produces systematically more absorption at short wavelengths than at long ones, so by measuring the absorption at various wavelengths we could estimate the thickness at 25 nm. That does not sound like much, but it was 20 times more than we had expected.

However, a literature search showed that beryllium dust forms thin flakes, like snowflakes. Like snow, beryllium dust is very porous. For snow, density is 1/20th that of water and so snow is 20 times thicker for the same mass. This is just a geometric property of flakes, so explains why the beryllium flakes create a layer 20 times thicker than a solid layer of beryllium.

Subsequent shots rapidly removed the dust, or melted it into a smooth layer on the electrode and vacuum chamber. As more and more of the dust was removed, the impurities in the plasma decreased.

Figure 3. The initial layer of beryllium oxide turned to beryllium dust after shot 1 (left) but the dust was removed shot by shot, leaving shiny smooth electrodes, (right) after 44 shots.

We measured the level of impurities three ways, with broadly similar results. First, we continued to monitor the build-up of dust on the windows. This dropped from 25 nm/shot on the first shot to 2.5 nm/shot on shots 2-11 to 0.35 nm/shot on shots 12-38, a rate of decrease of about 10% per shot. We don’t really know the porosity of the layers, so we can only use this measurement to set a maximum for beryllium deposition, assuming the layers are now solid metal. That maximum works out to 140 micrograms per shot, or about 5% of the deuterium in the current sheath, by mass. This would only increase resistivity by 10%, which is our current goal.

The spectrometer showed us that the only impurity detectable in the spectrum is beryllium. The strength of the beryllium line relative to the deuterium lines (identical to hydrogen lines) allows us a rough estimate of the abundance of beryllium at 0.16% by number or 0.7% by mass.

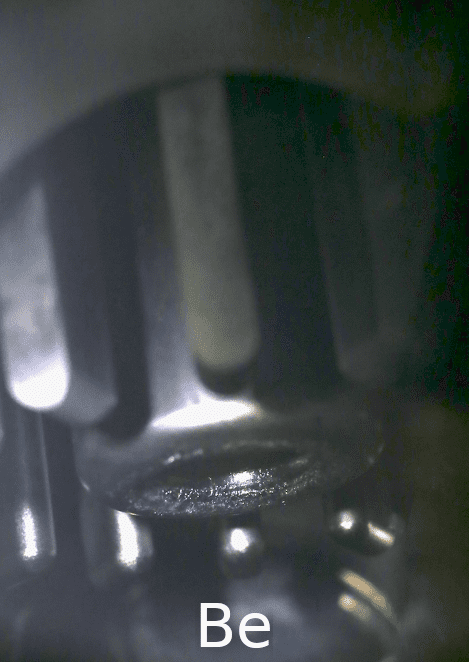

A third estimate comes from the dips in current that occur early in the shot. As we learned from the FF-1 tungsten shots, these dips are caused by vaporization and ionization of electrode material. About 7 J of energy is removed from the latest shots, enough to vaporize 70 micrograms of beryllium, or 2.5% of deuterium by mass. So the impurity level, consisting only of beryllium, is between 15% and 100% of our limit for impurities, meaning that low-impurity functioning has been achieved. We have another important indication that beryllium is eroding less than tungsten. With tungsten, the electrodes got rougher and rougher with use. We could see that the initially mirror-smooth surface became a bright white “matte” finish, reflecting light from all angles. But with beryllium, as the initial dust was burned off, the surface has become smoother, as indicated by the mirror reflection of light from a small area. (Fig. 4) Small scale ripples indicate that there has been some melting, but very little of the vaporization-caused roughness of tungsten. This matters, as a rough surface concentrates current in small points, leading to increased vaporization. In contrast, a smooth surface spreads out the current, minimizing further erosion. Of course, once we have filaments concentrating the current, this situation may change.

Figure 4. Beryllium anode after 44 shots (left) is still fairly smooth in the anode hole as shown by narrow bright reflection, while tungsten electrode after 56 shots in 2017 (right) was rough as shown by broad bright region. In both photos, the gap between the cathode vanes gives the scale of 1 cm.

Yield rising

While the beryllium overall has a small impact on the plasma, remaining concentrations of beryllium dust still have a big impact on the symmetry of the current sheath, especially at the start of the shot. This lack of symmetry, we think, is limiting the compression in the pinch and thus the density needed to achieve high fusion yield.

What we have seen, overall, is an irregular, but continuing, rise in fusion yield. Our first measurable fusion yield was on shot 3, with only 1.6 mJ. By shot 7, we were at 20 mJ. On Research Scientist Dr. Syed Hassan’s suggestion, we then scanned the fill pressure—changing for each shot the amount of gas we were putting in the machine and thus getting up to 60 mJ by shot 25. We then started altering the axial field coil current, which controls the amount of spin on the plasmoid, reaching 100 mJ on shot 43. By comparison, our record yield with FF-1 was 250 mJ, a quarter-J. Our first fusion yield goal with the beryllium is 1 J and we aim to reach 10 J by 200 shots. Of course, there are downs as well as ups within this overall trend, which can get a bit tense!

Excluding occasional pre-fires, when the whole capacitor bank does not fire together, we are getting about a 5% increase in fusion yield per shot. Some of this is due to our optimizing conditions, but most is probably due to the electrodes becoming progressively smoother and more symmetric after the initial big deposition of dust in the first shot.

We’ve seen no evidence yet that we have filaments that last until the compression phase, when the plasmoid forms. Once we get to that point, we expect a substantial jump in fusion yield. Until then we expect an incremental rise.

Within the overall pattern of rising yield, there have been as many as seven shots in a row with consistency in yield to within 10%. That is better consistency than we have seen with FF-1, an encouraging observation.